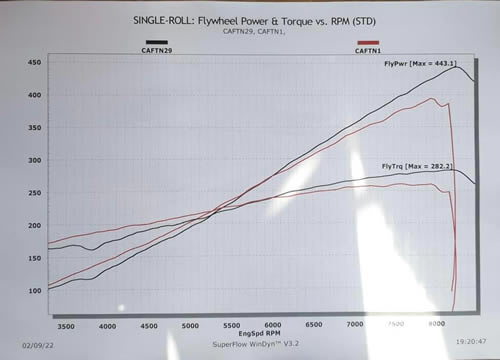

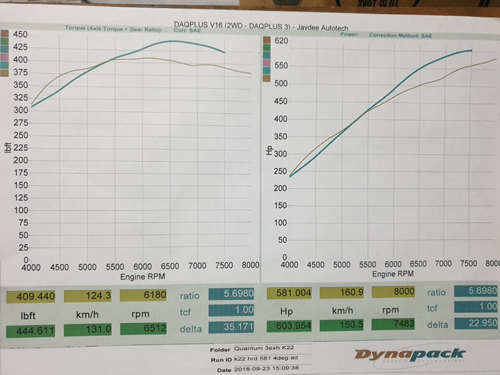

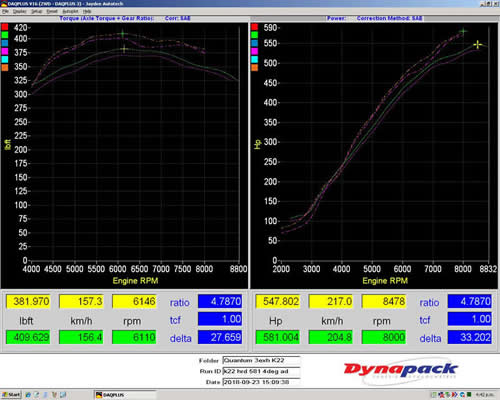

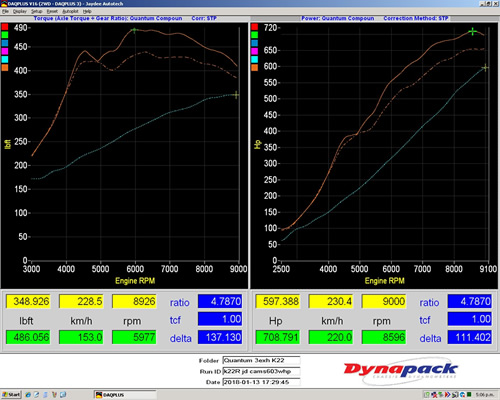

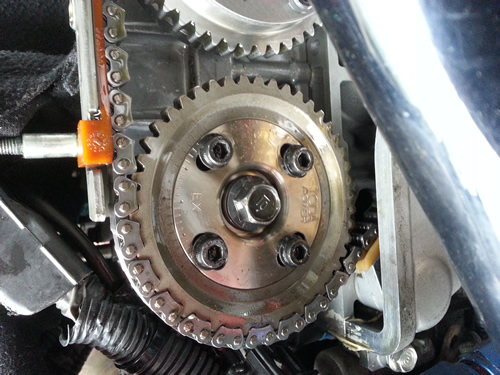

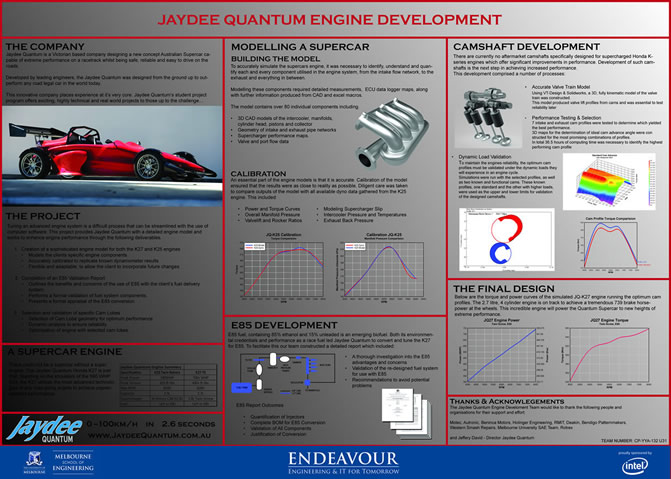

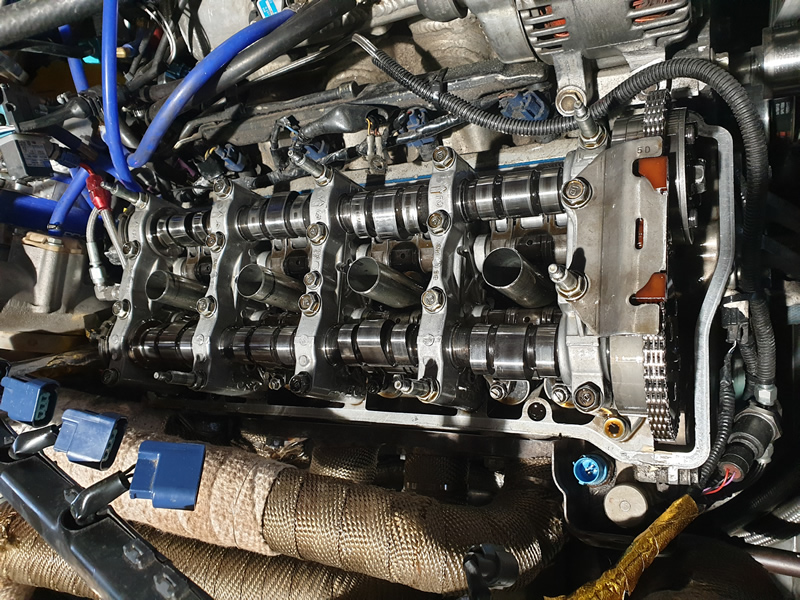

Quantum GP700 Honda K20 K24 Supercharger and Turbo CamshaftsI have developed 3 different camshafts for boosted applications with dyno results from 600whp to over 700whp. Rotrex K20/K24 Camshafts, TVS or Eaton K20/K24 Camshafts, and our Turbo Camshafts. Our forced induction camshafts for each application are different so we don't recommend you attempt to run Rotrex camshafts in a TVS installation, or vice versa, etc. So don't fool around with the wrong combination or you won't get the best results. I started the camshaft design and research in 2005 with Joe M who has since passed away. We were both SC enthusiasts and were upset that no Honda K series SC cams were commercially available. It's taken me this long.....as many K series cam profiles create chain or tensioner issues which was a concern. I also acknowledge the modeling work that the Melbourne University Thesis Students completed including Andrew David. They worked incredibly hard calculating the valve train loads and stresses. My test setup is a K24 ERL sleeved block, 89mm x 90.7mm so K22, 9.2/1 for future high boost, JD inlet and exhaust manifolds, 3" 3x pass muffler in the Quantum GP700, JD head porting, 74mm TB (now upgraded to 90mm post dyno in 2018), E85. Rotrex K20/K24 Camshafts K22, Rotrex C38-91, 603Whp Jaydee GP700 Rotrex Cams compared to 505Whp K20Z1 Cams Since this dyno graph I have worked on different small lobe profiles to improve the non iVtec performance of the Rotrex, progressively trying different lifts. The on road drive ability is really impressive. The second graph is a stock FN2 (K20Z) with a TTS kit, before and after installing the GP700 Rotrex camshafts. No pulley changes. Less blow through gives more boost. I was not involved in the installation or dyno tuning. Our camshafts have a fair bit of advance on the grind. Could also be the TTS inlet manifold is hurting low velocity airflow compared to traditional inlet manifolds? Great gains up top. Thanks UK Supercharger Repairs and EFI Parts for the testing and feedback. TVS or Eaton K20/K24 Camshafts To develop TVS camshaft profiles we built an experimental mounting/outlet housing to use a TVS2300 in a custom made Harrop housing. This setup was capable of up to 600whp and 24psi boost. With stock camshafts our K22 TVS2300 Harrop housing started at 526Whp with a 65mm pulley @8000rpm. We tried adjusting lobe centers and improved to 547.8Whp. We then fitted our revised Jaydee GP700 TVS Cams. Boost increased a fair bit as our camshafts have less blow through. So we fitted a 71mm pulley. This made 581Whp initially. Over the next few weeks we worked on lobe centers and a different exhaust grind improving to 604Whp. We used boost control to reduce the torque at 4000rpm to smooth out the torque rise as wheel spin was an issue and I did not want to overload the rods at lower engine speeds. After a couple of weeks on the dyno we ran out of dyno time, fuel capacity and inspiration to rev to 9000 with the GP700 cams. Clearly we were past the torque peak so maybe another 10 or 15whp might have been possible. Our aim was the camshaft testing so I didn't see this as a big need as we had achieved our aim. I say again that the TVS and Rotrex grinds are not the same profiles. Turbo Camshafts (Compound Charged) Our test engine was the same K24 ERL block 89mm x 90.7mm so K22, 9.2/1, JD inlet and exhaust manifolds, 3" 3x pass muffler in the Quantum GP700, JD head porting, 90mm TB, E85. Our Rotrex C38R was retained on the Quantum GP700 and a EFR9174 turbo with twin 45mm wastegates was installed so we were actually testing with a compound charged system. This has proved to be hands down our best engine combination. The low speed under 4000rpm drives like a supercharged car with instant throttle response and linear power, and above 4000rpm the EFR9174 boost multiplication creates amazing midrange. (Even stronger than the TVS). The combined efficiency may not be as good as just a Turbo but the gain in drive ability we consider to be well worth it. At 9000rpm the supercharger drive losses are robbing over 100HP from the crankshaft. For a track only car constantly at high rpm's then perhaps I would remove the Rotrex?, but the Quantum GP700 is 80/20 street/track and the linear and instant throttle response of the supercharger is too good to give away for efficiency gains. Our asymmetrical inlet camshaft profile has proven great results with centrifugal compressor forced induction. So with this starting point. We tried 5 different exhaust camshaft profiles over a 9 month period with the last 3 being custom grinds from billets. Each combination was fully tuned and a range of exhaust centre lines were tried to understand the interactions of overlap, closing time with turbo spool, top end, etc. When I got to 650whp I almost gave up a that seemed to be the limit. But I persisted grinding another secondary lobe idea and this was installed yielding an instant 30hp gain. I was wrapped. With fine tuning we found the sweet spot and an amazing 708Whp @24psi. I still can't believe it knowing we are spinning the C38R with losses of over 100hp at the crankshaft. This I believe accounts for most of the torque drop over 7500rpm.

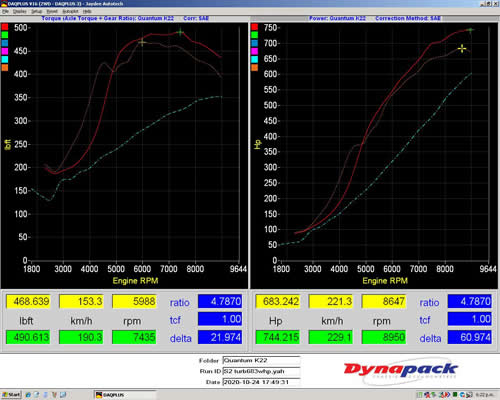

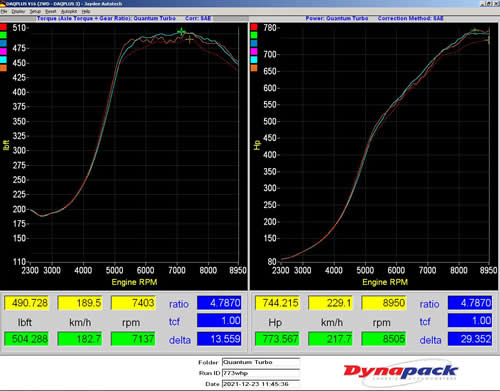

The blue graph is Rotrex only, the dotted orange was the best other exhaust camshaft and the solid orange is the final result. There is some more adjustments to the wastegate tuning between 4500 to 5500rpm with the transition from Rotrex to Turbo but after so much effort it can keep for the future. Turbo Camshafts (only EFR9174, no supercharger) In October 2021 we removed the C38R to test a straight turbo installation. No tuning was done. We had to limit the DBW before the Turbo to 82% throttle or boost was climbing above the 24psi and we wanted to do a straight comparison with the compound C38R EFR9174 setup. The twin 45mm wastegates combined with the poor exhaust manifold was over boosting. So first we tested the compound setup at 82% DBW and 24psi. This yielded 683WHP. Then removing the C38R power climbed to 744Whp. A comparison graph in blue with a 603Whp Rotrex only is also below. Our Honda K series has come a long way in 15 years. A few months later in December I revisited the tune. I experimented with the wastegates opening compared to the cold air post inter cooler bypass. This was to optimize the exhaust back pressure for a combination of compressor efficincy and combustion chamber scavenging. The result was a staggering 774WHP with no change in boost, a gain of 30whp, still 24psi. General Information The Jaydee GP700 cams are billets made in Australia from scratch. They are made this way as the material chosen can be induction hardened providing a more stable and stronger material and totally eliminating possible failures from a cast core. They have been in the GP700 for 1.5 years (Feb-2019), plenty of dyno time, road driving and track testing. So far I have not adjusted the valve clearances. My design is a different approach to traditional SC cams as I discovered that a centrifugal supercharger airflow and pressures at overlap are quite different to a typical roots blower. As a result, cam lobe centers, lift and duration ideas are not optimum. I have a feeling that the GP700 Rotrex cams might work really well in turbo engines as they seem less effected by exhaust back pressure than stock cams and build power quicker than any combination I have tried. As with the Rotrex, the TVS cam efforts focused on minimum blow through as these blowers move huge air. By trapping more charge air during the overlap period blower speeds were reduced for the same boost pressures. With the lower blower speeds heat and SC drive losses reduced and power increased. Everything is a balance. Please note your results may differ from mine. I am always wanting to improve our knowledge and engine performance. As they are made here in Australia they are priced in Australian Dollars at $1640 plus shipping. (shipping to the USA is about $100 Aus.) Our dollar is approx 0.68US to 0.73, however exchange rates do move around so check the exchange rate at the time. So about $1200 USD for a pair + shipping. This is a hobby and interest for me so I am getting them made in batches and require payment first. Depending on the application I have developed more aggressive primary lobes or if fuel consumption is important I use stock primary lobes. You will need typical stage 2 springs around 100 lbs seat. I run IRL springs from 4P and the K22 power is still building at 9500rpm. Please email me for orders jeff.david@quantumgp700.com.au or you can comment on the Facebook thread for information to save duplicating questions. Dyno graphs are only part of the story. The K22 C38-91 cammed engine is really smooth and has a noticeably different exhaust sound. Motec logging data from the track is showing higher acceleration rates than the K27 with twin rotrex C38-91's (from 2014) which is confusing as the K27 was a monster on the dyno and on the track. But you cannot argue with data, and GPS speed overlays.... At the time the TVS GP700 cammed engine had the highest acceleration rates I had seen peaking at 1.35G @ 100Kph. Amazing the grip a RWD transverse mount chassis can produce on R spec tyres. This combination is a great street motor but creates too much heat for road racing, which is my personal interest. This inspired me to try the compound Rotrex Turbo. The final Rotrex Turbo is even better on the road without the inlet heat issues of a TVS at high boost. It's an unbelievable engine. I hope this answers your questions.

|

|

|

|

|

The students Endeavor project display.

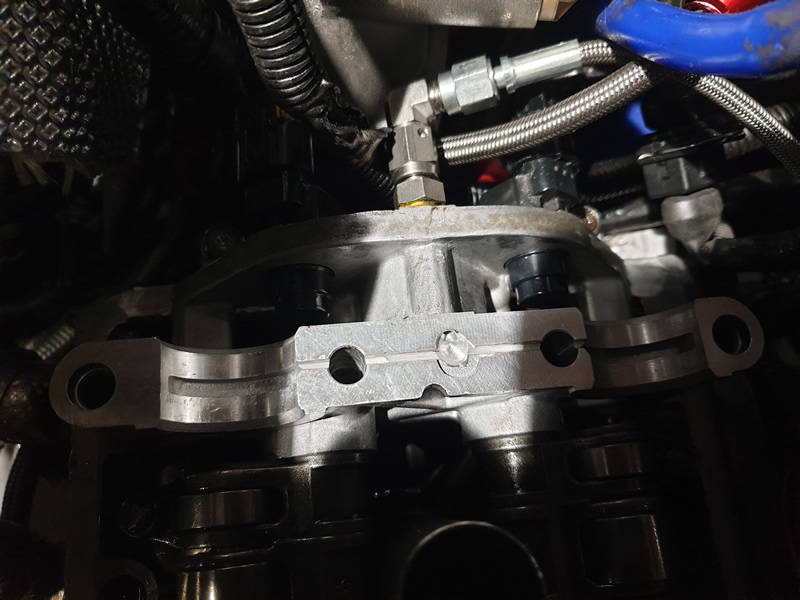

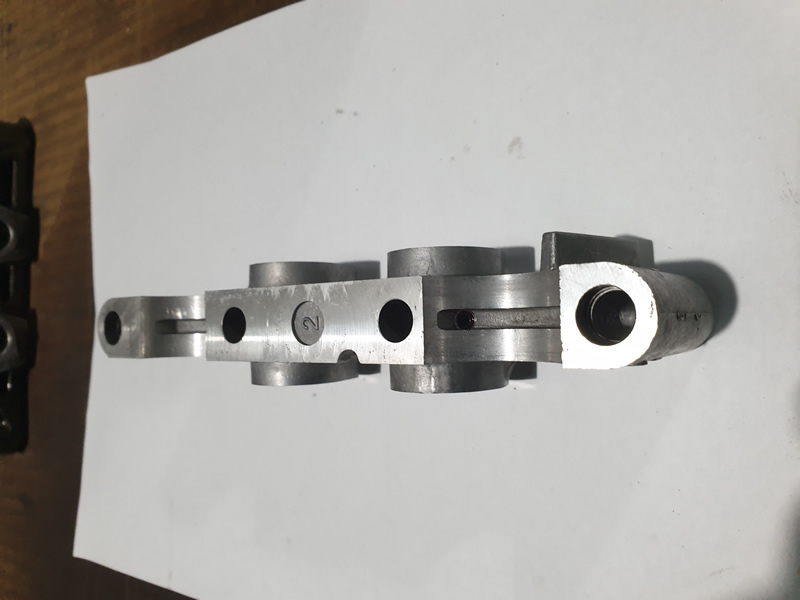

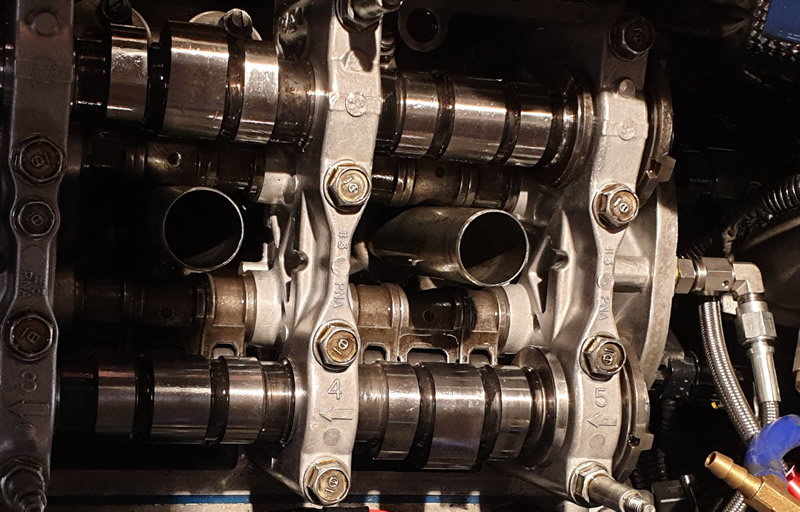

K20/K24 Cam Tower Saddle Modification Why do we see wear in the cam towers on K20A and K24 motors? This information was explained to me by a friend Joe McCarthy (RIP) in around 2004. At the time he developed the modification as he was experiencing issues with his engines with both stock Honda and the IPS camshafts they were developing. He advised making the cam tower modifications. I did not have any issues then. Many people have copied his idea since. I now have this issue since I raised VTec from 2800 to 5500rpm and have been doing more track days with high oil temperatures. I believe it’s the combination of oil pressure, oil weight and temperature, VTec engagement RPM’s, valve spring seat pressure and high lift camshafts. The camshaft journals oil feed is from two small holes in #2 cam cap journal, one in the inlet cam and one in the exhaust cam. These holes are supplied from the oil in the rocker shafts. The #2 cam cap journal then progressively feeds camshafts journals #3, #4, and #5. Before VTec is engaged the oil pressure in the rocker shafts is very low to prevent the VTec pins engaging, typically 6psi. Thus the oil pressure feeding camshafts journals #3, #4, and #5 is also very low at around 6psi or less. By carefully milling a slot in #5 tower Joe supplied oil from a cross drilled external feed into the camshaft journal. I was lazy and cut mine with an angle grinder! This way isn’t as good as Joe’s method as you then need to plug the inside of both the rocker shafts to stop high pressure oil engaging Vtec. In the cross drilled section I created a restriction hole the same size as Honda’s one that we need to plug on cap #2. I then plugged both the oil feed holes on cap #2 saddle, one on the inlet and one on the exhaust journal. A UNC allen screw with Locktite 243 did the job. I used a -3 hose for the external feed with my oil pressure sensor in the line located close to the block gallery port. There are a number of suppliers like Tructuff who supply kits if you choose to buy buy your oil modification. |

|

|

|

Jeff during business hours. 0420 355 307 email: jeff.david@quantumGP700.com.au

|

|